Are HDPE seats Comfortable for Stadium Use?

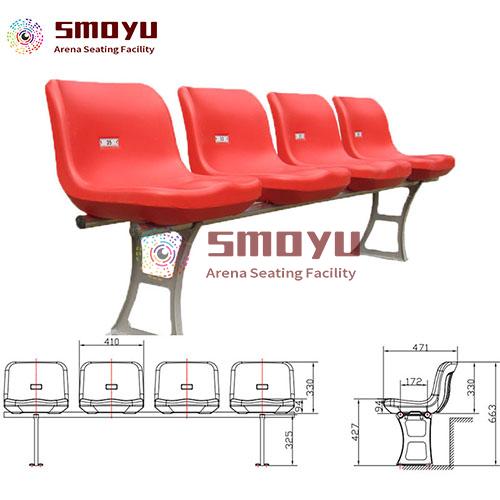

HDPE (High-Density Polyethylene) stadium seats are a popular choice in arenas, schools, and sports facilities worldwide. At Shanghai Smoyu Industry Co., Ltd, we manufacture ergonomic HDPE seating solutions using advanced hollow blow molding. But what exactly makes HDPE comfortable, and why is it the preferred seating material? Let’s explore.

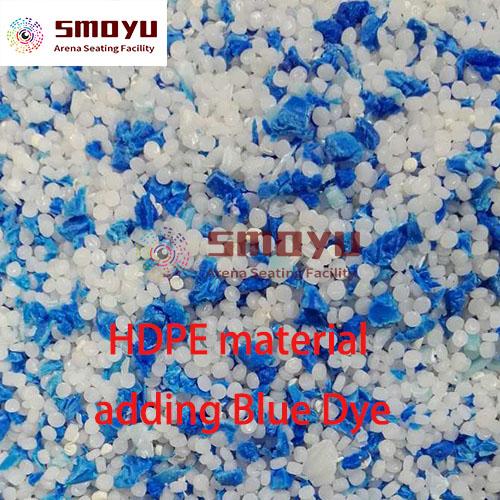

1. What is HDPE material?

HDPE is a strong, weather-resistant thermoplastic resin. Introduced in the 1950s, it has become one of the most widely used plastics due to its durability, cost-effectiveness, and safety. These characteristics make it perfect for stadium seating projects worldwide.

2. Key Benefits of HDPE Stadium Seats

- ✅ Excellent impact resistance and durability

- ✅ Safe, odorless, and non-toxic material

- ✅ Resistant to weather, UV rays, and corrosion

- ✅ Low water absorption, ideal for outdoor use

- ✅ Comfortable ergonomic design for long events

3. Applications Beyond Stadiums

HDPE is not limited to stadium chairs. It is also widely used in:

- Injection molding: food containers, bottle caps, toys

- Blow molding: plastic bottles, tanks, and stadium chairs

- Extrusion: water/gas pipes, tubing

- Rotational molding: storage barrels, industrial containers

Thanks to these properties, HDPE stadium seats ensure comfort, safety, and long-term reliability for spectators across the globe.

FAQ: Frequently Asked Questions

Q1: Are HDPE seats safe for outdoor stadiums?

Yes. HDPE is UV-resistant and waterproof, ensuring long-lasting performance.

Q2: Do HDPE seats require much maintenance?

Minimal maintenance is needed – they can be cleaned easily with water and mild detergent.

Q3: Can HDPE seats be customized?

Absolutely. We offer multiple colors, designs, and installation options for different venues.